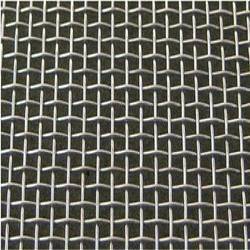

BIS Galvanized Wire Mesh

BIS Galvanized Wire Mesh Specification

- Hole Shape

- Square / Rectangular

- Length

- 15-30 meter rolls

- Wire Gauge

- 14 to 23 SWG

- Surface Treatment

- Galvanized

- Aperture

- 12 mm to 50 mm

- Product Type

- Wire Mesh

- Mesh Type

- Galvanized Iron

- Mesh Style

- Welded / Woven

- Material

- Iron / GI

- Alloy

- Non-Alloy

- Application

- Fencing, Construction, Industrial, Agro, Poultry, Security

- Dimensions

- Custom as per requirement

- Wire Diameter

- 0.6 mm to 2.00 mm

- Weight

- Varies with mesh size and roll dimensions

- Color

- Silver

- Manufacturing Technique

- Spot Welded or Twill Weave

- Tensile Strength

- 350550 MPa

- Coating Thickness

- Approximately 30-60 gsm

- Corrosion Resistance

- High

- Standard

- BIS (ISI Marked)

- Edge Type

- Cut Edges or Folded Edges

- Usage Temperature

- Up to 200C

- Packing

- Waterproof Paper Wrapped

- Roll Width

- 0.6 m to 1.8 m

BIS Galvanized Wire Mesh Trade Information

- Payment Terms

- Cash Against Delivery (CAD), Cheque

- Main Domestic Market

- All India

About BIS Galvanized Wire Mesh

ISI Galvanized Wire Mesh

The offered BIS Galvanized Wire Mesh is widely demanded in poultry firms, agricultural field, constructional sites and many other industries. Banking on our hi-tech manufacturing production unit, this wire-mesh is manufactured with high precision to meet the set market standards under the guidance of our adroit experts with the utilization of fine grade metal-alloys. Apart from this, offered BIS Galvanized Wire Mesh is available in diverse thicknesses, finishes, and other specifications at rock-bottom prices.

Features:

- Available in a variety of sizes, gauges, alloys, and widths

- Made from top quality materials

- Easy to install & maintain

- Well knowing for longer functional life and high tensile strength

- To ensure the quality, it is designed under the observation of technical experts

Robust Corrosion Resistance

Our galvanized wire mesh is treated with a high-quality zinc coating (3060 gsm), providing reliable corrosion resistance even in challenging conditions. This makes it ideal for both indoor and outdoor applications, ensuring long-term durability and safety wherever its used.

Customized for Your Needs

Choose from a variety of roll widths (0.6 m 1.8 m), lengths (1530 meters), wire diameters (0.62.00 mm), and aperture sizes (1250 mm), or request custom dimensions to suit your specific project. Both cut and folded edge options are available, offering flexibility for installation.

Versatile Manufacturing Techniques

Manufactured using spot welding or twill weaving methods, our mesh offers structural integrity and stability for multiple uses. Its robust build accommodates high-stress environments and supports various industrial, agricultural, and security needs across India.

FAQs of BIS Galvanized Wire Mesh:

Q: How is BIS Galvanized Wire Mesh manufactured?

A: The wire mesh is produced using premium iron or galvanized iron wire, with construction methods such as spot welding or twill weaving. The mesh is then galvanized with a coating of approximately 3060 gsm, ensuring a durable and corrosion-resistant finish that meets BIS (ISI) standards.Q: What are the main benefits of using BIS Galvanized Wire Mesh?

A: Key benefits include high corrosion resistance, strong tensile strength (350550 MPa), and versatility for various applications. Its galvanized surface prolongs service life, making it suitable for projects requiring longevity and performance in demanding environments.Q: When should I choose a welded mesh versus a woven mesh?

A: Welded meshes are typically chosen for applications requiring higher strength and rigidity, such as fencing and security. Woven meshes (like twill weave) are more flexible and are ideal where adaptability and custom shapes are needed, such as in filtration or lightweight barriers.Q: Where can BIS Galvanized Wire Mesh be used?

A: This mesh is widely used across fencing, construction, industrial sectors, agro-based activities, poultry farms, and security installations. It adapts well to both indoor and outdoor environments, thanks to its high resistance to rust and adaptability in dimensions.Q: What process ensures the meshs corrosion resistance?

A: Each wire strand is coated with a layer of zinc through the galvanization process. This forms a barrier against moisture and chemicals, drastically reducing the chances of rust or corrosion, especially suitable for exposure to the elements.Q: How do I determine the right roll width, length, and aperture for my needs?

A: Choosing the appropriate specifications depends on your application. Consider the purpose, required strength, and area to cover. Standard widths range from 0.6 to 1.8 meters, lengths from 15 to 30 meters, with aperture sizes from 12 to 50 mm. Custom options are available for unique project requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Netting (Wire Mesh) Category

BIS Crimped Wire Mesh

Minimum Order Quantity : As per requirement Piece

Application : Other, Industrial Sieving, Fencing, Construction, Mining, Quarrying, Filters, Safety Guards

Aperture : 1 mm to 100 mm

Color : Silver, Black

Wire Gauge : 10 Gauge to 25 Gauge

Length : as per requirement (typically up to 30 meters)

BIS Bird Wire Mesh

Minimum Order Quantity : As per requirement Piece

Application : Other, Poultry farms, Agriculture, Bird cages, Fencing

Aperture : 1 inch

Color : Silver

Wire Gauge : 16 Mesh

Length : 30 m

ISI Hexagonal Wire Mesh

Minimum Order Quantity : As per requirement Piece

Application : Other, Fencing, Poultry, Gabion, Construction, Protection

Aperture : 0.75, 1, 1.25, 1.5, 2 (custom sizes available)

Color : Silver (Galvanized), Green (PVC coated), or as specified

Wire Gauge : 2.5 mm to 0.7 mm

Length : 15 m, 30 m, or as required

Industrial Wire Netting

Minimum Order Quantity : As per requirement Piece

Application : Other, Fencing, Construction, Industrial Use

Aperture : 12 mm

Color : Silver

Wire Gauge : 14 Gauge

Length : 30 Meter Roll

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry